| |

|

|

| |

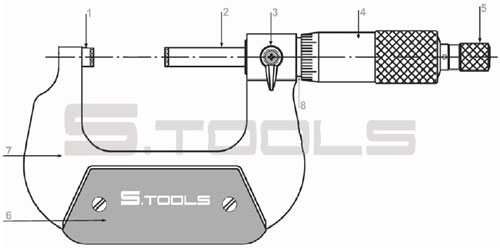

1- Anvil with carbide measuring face

2- Spindle with carbide measuring face

3- Locking level

4- Thimble |

5- Ratchet stop driving knob

6- Heat isolation plate

7- Frame

8- Sleeve |

1. Clean the micrometer gently before use. Make sure the measuring faces are clean.

2. Remove cutting chips, dust, burrs and other foreign substances from the piece to be measured.

3. Setting standard and adjusting wrench:

They are used to calibrate micrometers. Micrometers should be calibrated frequently. The length of the setting standard is 25mm for range 25-50mm, 50mm for range 50-75mm and 75mm for range 75- 100mm. The micrometer with range 0-25mm doesn’t have setting standard and it can be regarded as having a standard rod of zero length. The reading must be the same as the length of setting standard when the micrometer ‘measures’ the setting standard. For example, when the micrometer with range 25-50mm‘measures’its setting standard(length 25mm), the reading must be 25mm exactly.

Otherwise you should adjust the micrometer. Put the small point of the adjusting wrench into the small hole on the sleeve which is near the locking lever, rotate the sleeve to make the zero line of the thimble align with the horizontal line of the sleeve. Another end of the adjusting wrench is used to fix or unfix the ratchet stop.

4. How to measure:

Let the anvil contact with the workpeice first. Rotate the thimble or the ratchet stop till the spindle is close to (but not in contact with) the workpeice. Rotate the ratchet stop until you hear a click from the ratchet stop. |

5. Locking lever:

Tighten this lever to lock the reading when you have to remove the

micrometer before reading.

6. How to read

Example 1

A: 35

B: 0.12

----------

C: 35.12mm

Example 2

A: 42.5

B: 0.148 (8 is estimated)

------------

C: 42.648mm

A is the line of the sleeve which is on the left of the thimble.

B is the point on the thimble which aligns with the horizontal

line on sleeve.

C is the reading |

|

The graduation on the sleeve is 0.5mm. One rotation of the thimble makes 0.5mm (1 graduation) step on the sleeve.

7. Precaution for measurement:

Never rotate the thimble to let the spindle contact with the workpeice, which may damage the precision thread inside the sleeve. Please grip the heat isolation plate if you hold the micrometer for a long time, in order to prevent heat transferring from your hand to the micrometer. If the workpeice and the micrometer are a different

temperature, an error of accuracy may be caused.

8. Measuring faces should be carefully prevented from being scratched, hit or rusty. Do not operate abruptly,

|

|

|

|

|

|

|