| |

|

|

| |

|

Digital calipers are extremely economical and accurate measuring instruments. They usually have a resolution of 10 μm with an accuracy of 30 to 40 μm. This high performance and cost efficiency is achieved with the use of multiplate capacitive sensors.

Capacitive sensors are extremely rugged and simple to build. They are highly linear and immune to mechanical and electronic noise. However, since they rely on capacitance, they are sensitive to liquids. Any liquid that bridges the capacitive plates increases the capacitance. A drop of oil can increase the capacitance by a factor of 80!

How Digital Calipers Work

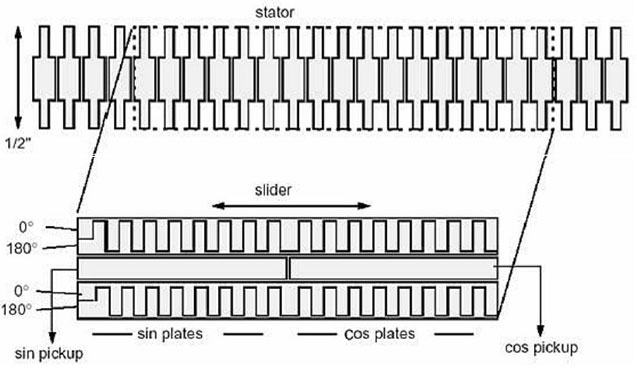

Digital calipers use multiple plates to form a capacitive array that can senses motion accurately. There is a stator and slider ("rotor") plates in a digital caliper. The stator is embedded in the metallic ruler on which electronic housing slides. The electronic housing contains the slider.

Figure 1 Multiplate Electrodes Stator

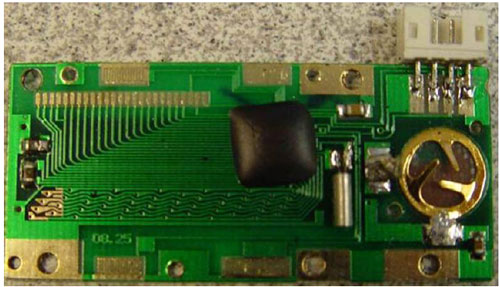

Picture 1 Multiplate electrodes etched on PCB of a digital caliper

The stator pattern is fabricated on the top copper layer of a standard glass-epoxy laminate and glued to the stainless steel bar of the caliper. The slider pattern shown is similarly abricated on PC laminate, drives a 100 kHz signal through the sin/cos plates to the stator electrodes, and picks up AC voltages at the two central pickup plates which describe

sin(displacement) and cos(displacement) signals.

Separate sin and cos signals are needed to determine direction of motion. The combination of plate-counting digital circuits and analog interpolation between plates yields 0.0002"accuracy over 6" with standard PC fabrication methods. This application uses a small watch battery, and shows the microamp-level current consumption possible with the technology.

Also please refer Capacitive Sensor information. | |

|

|

|

|

|